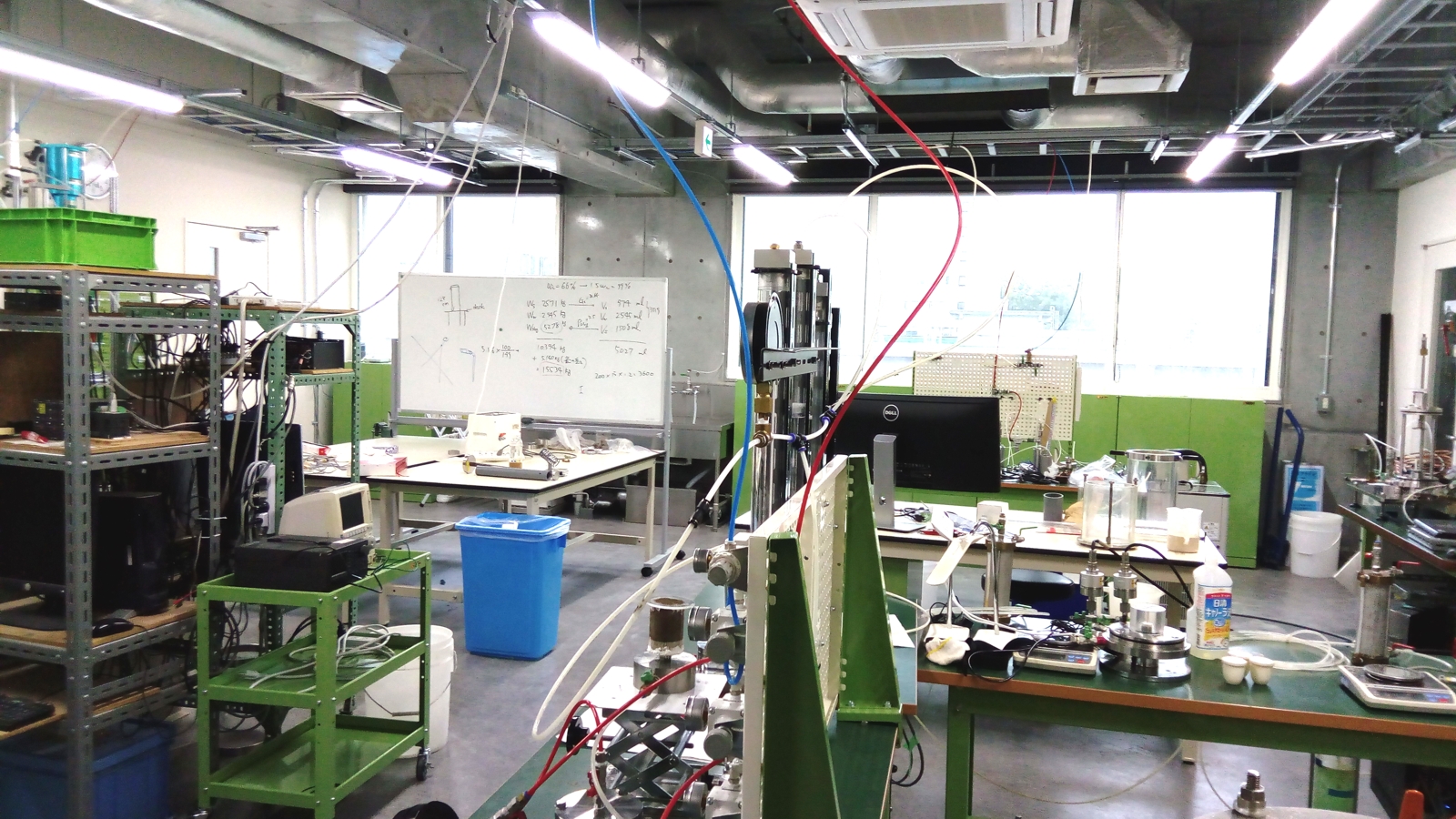

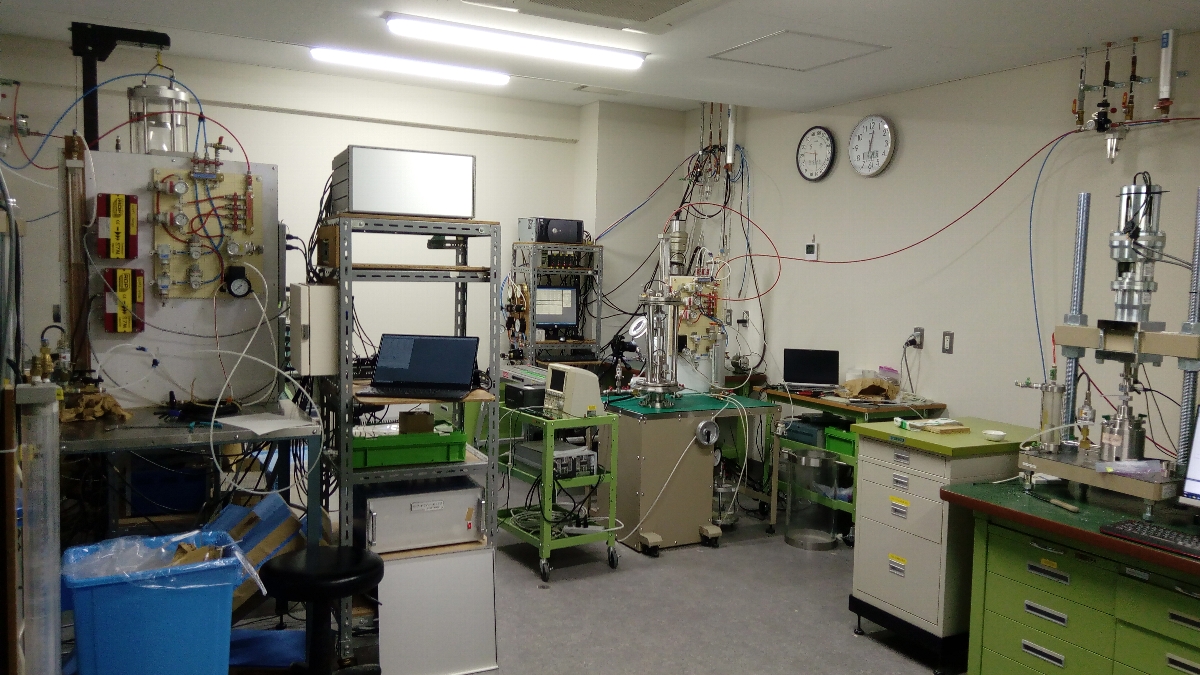

Laboratory

Soil Mechanics Laboratory (2) and constant-temeprature room

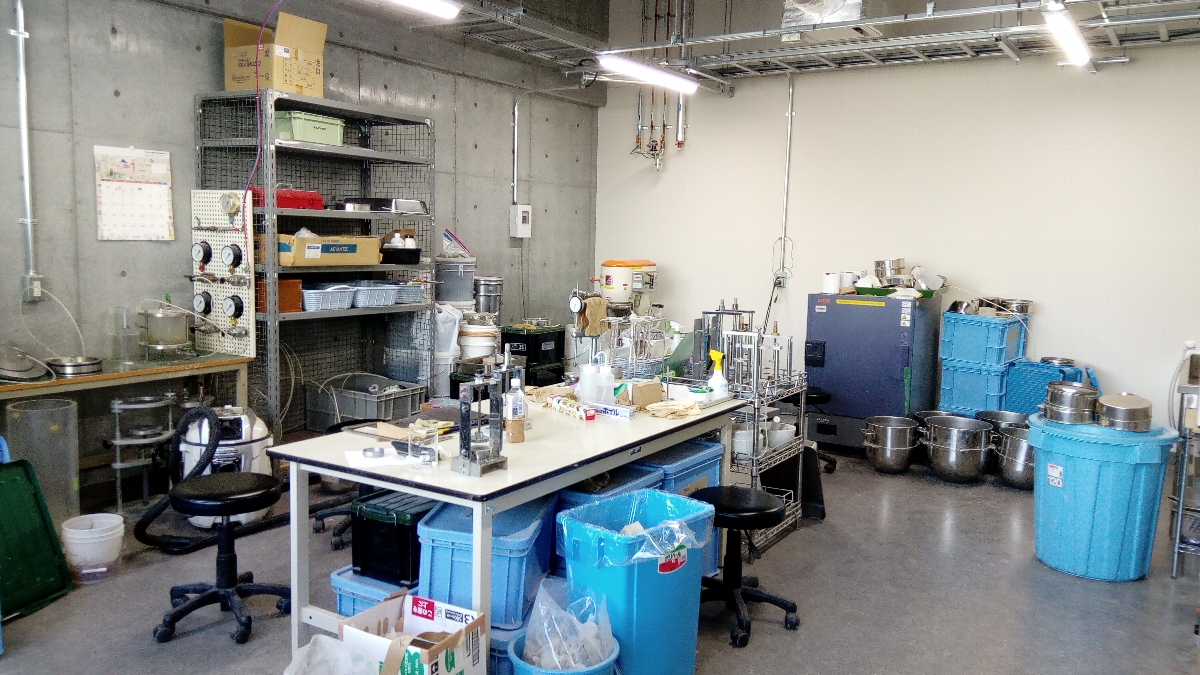

Sample preparation room

Introduction

Our group shares soil laboratories with Professor Watabe's and Dr. Fukuda's groups. Some facilities are shared with Analytical Geomechanics (Professor Ishikawa, Dr. Isobe and Dr. Yokohama) group. All the laboratories are in Civil Engineering Research Building, newly completed in 2017.

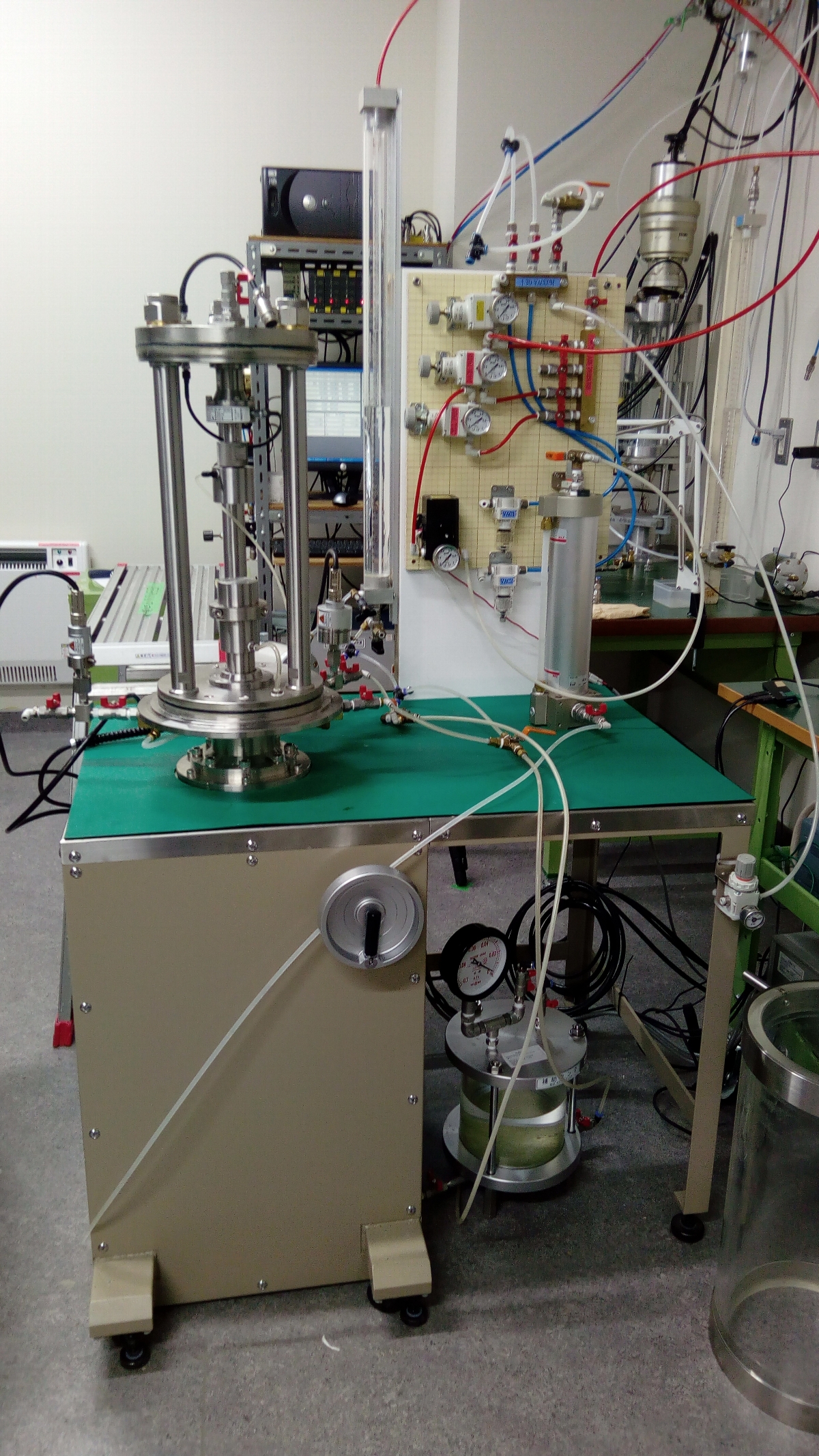

Soil Mechanics Laboratory (2) and attached rooms were designed by Nishimura when the whole building plan was drafted. All the facilities, including water-proof floor slabs, pneumatic/hydraulic plumbing, electric wiring, lighting and insulation, are optimised for the machines we have. All the rooms are fully air-conditioned, and particularly strcit temperature control is possible in the constant-temperature room, where we keep advanced machines. Any sample preparation is conducted in a seprate room, to keep the main laboratory free from dust.

In addition to these rooms, we have large laboratory and student demonstration laboratory in different floors.

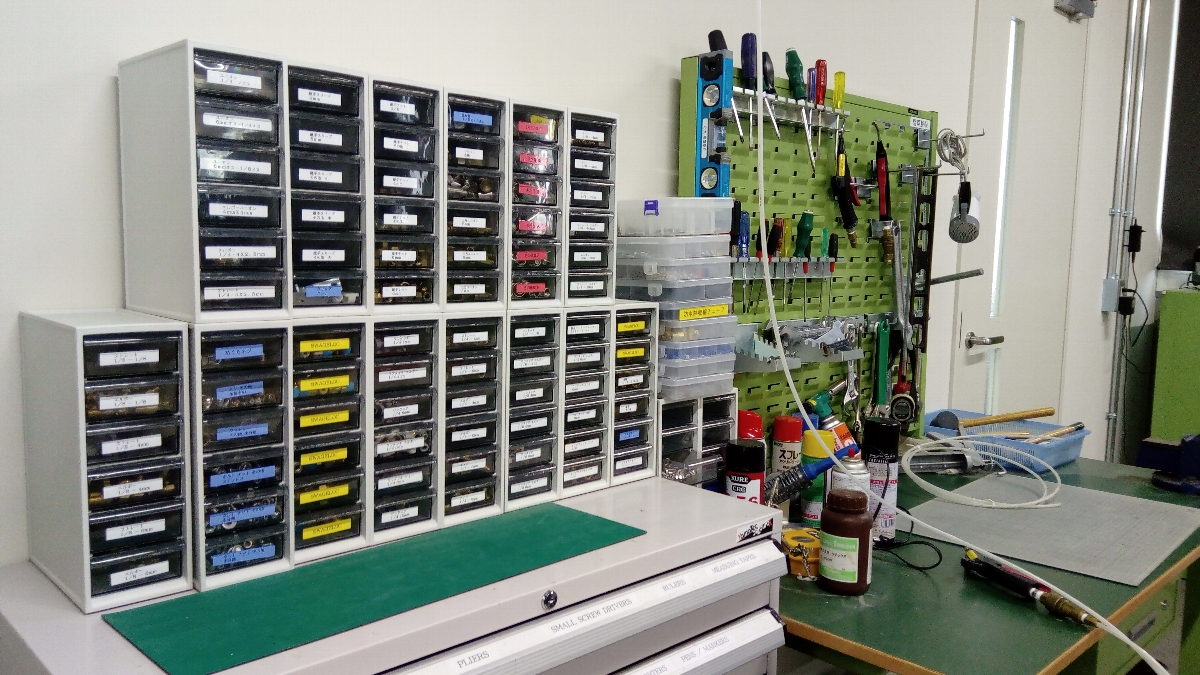

Our lab stores (probably) hundreds of thousands of mechanical parts, so that we can improvise new experiments on the spot. Tidying up is the most important part of the lab work.

Much of the apparatus in our lab was originally developed. Our work bench is always busy with new development, updating, and repairing work.

Testing Machines

Our lab has many soil testing machines, including 10 triaxial machines, 3 CRS oedometers, 4 incremental-loading oedometers and 2 direct shear machines. More unconventional equipment includes hollow cylinder apparatus, one-dimensional freeze-thaw apparatus, CP-type soil-water chracteristics testing machine, temperature-controlled oerdometer, needle-penetration machine, inter-connected oedometers, etc. Many of these are more than 20 years old but well maintained and work like new machines.

Megatorque Motor-driven Triaxial Apparatus

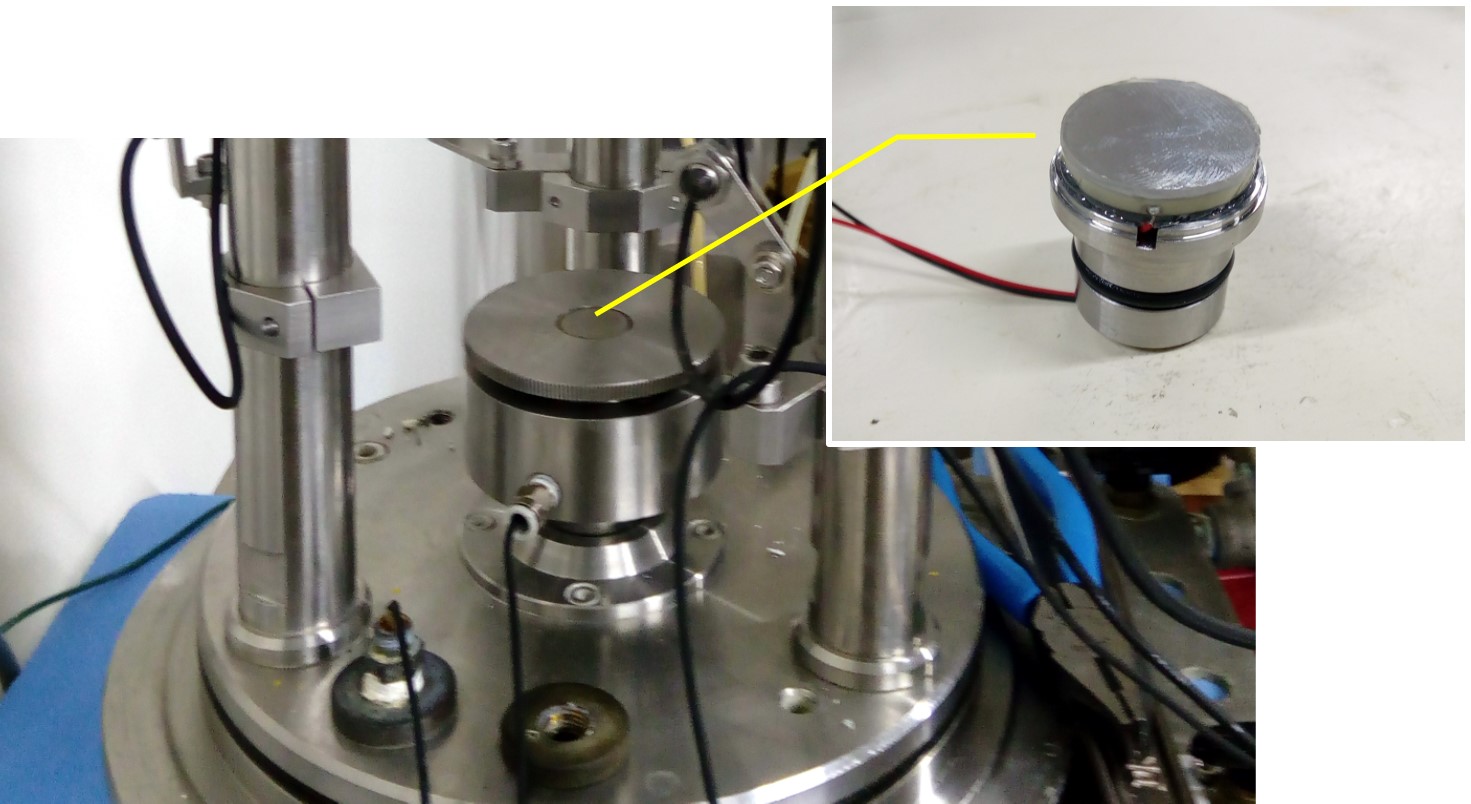

We have 6 sets of triaxial apparatus with Megatorque Motor (NSK Ltd.) as axial driving unit (we are calling them MEGA I, MEGA II, ..., MEGA VI). All the machines work in a same way, but have their own customised parts.

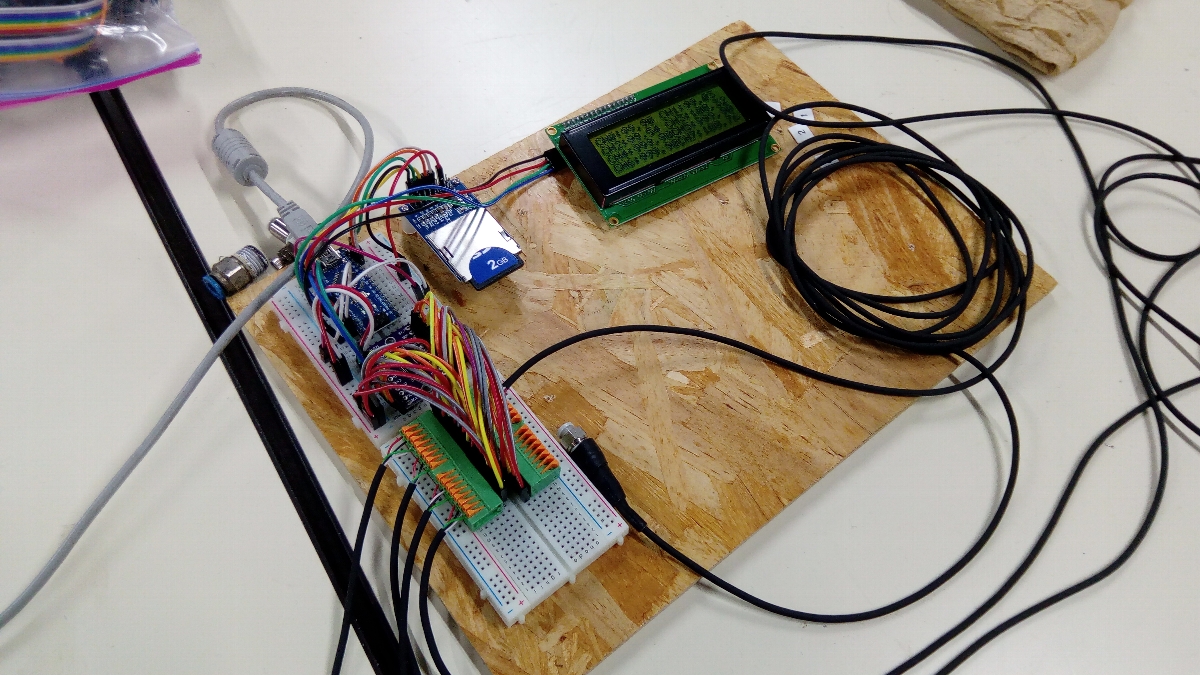

When small-strain stiffness is measured, the triaxial apparatus can house a suite of local transducers (such as water-proof LVDTs and proximity transducers) and piezo-electric oscillators. Cockpit, a home-grown integrated software for lab-test control and data acquisition, allows a variety of different loading schemes to be implemented, including cyclic tests, automatic multi-stage tests and creep tests, for example.

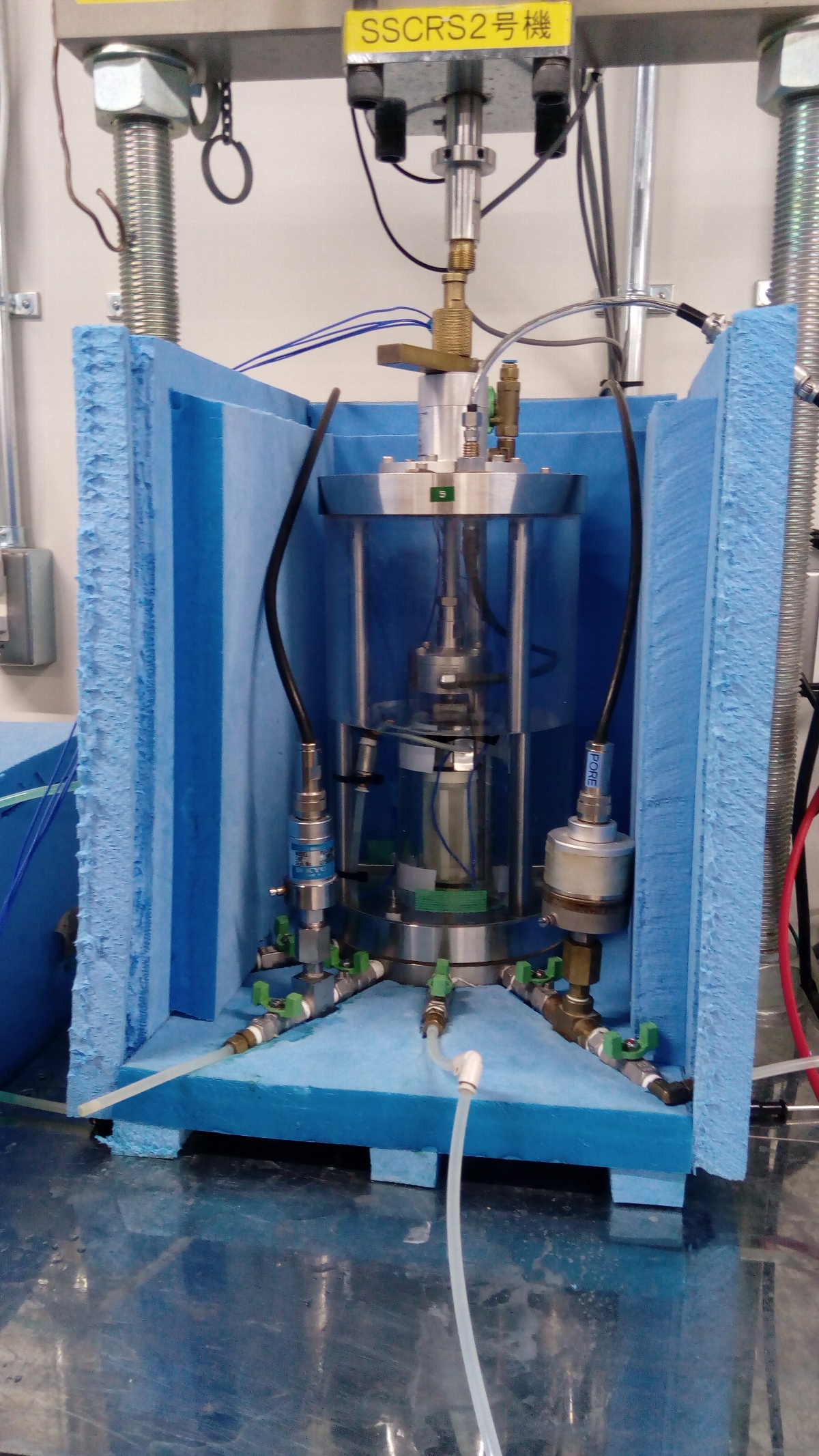

One of the triaxial machines is used for frozen soil testing. The apparatus is individually insulated, and low-temperaure tests can be conducted in a room temperature. A new freezing method has been devised, which allows a quick one-dimensional freezing to prevent formation of ice lenses in the soil specimen. This process reproduces quick freezing under confining pressure, relevant to new generation artificial ground freezing.

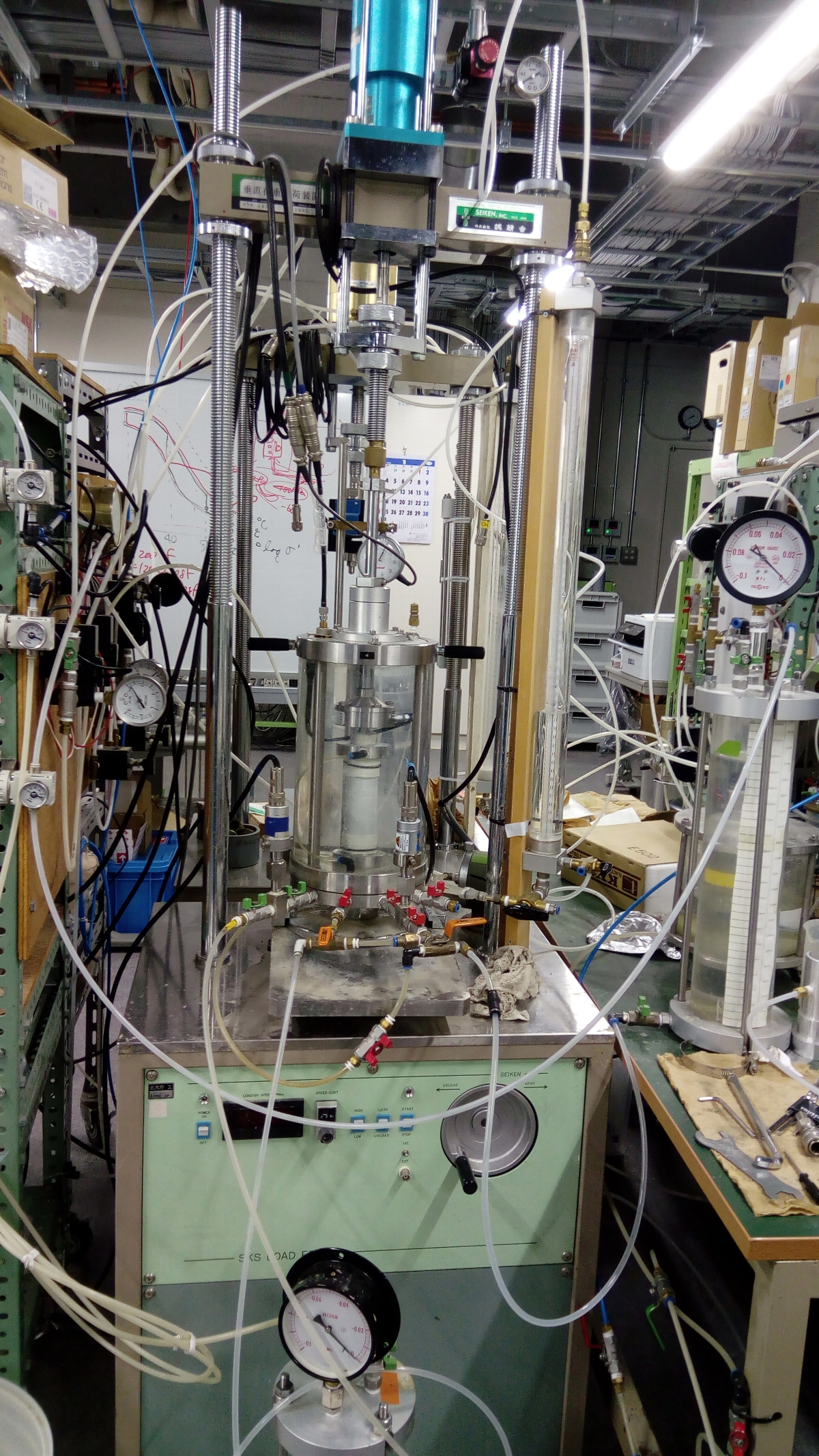

Triaxial Apparatus (Seikensha-type)

We have conventional 4 Seikensha-type triaxial machines. The pressure chamber, plumbing, electronics and software have been updated to our original design. This apparatus can be used for general purposes, and the loading frame can be used for other types of tests, such as unconfined compression tests and CRS oedometer tests.

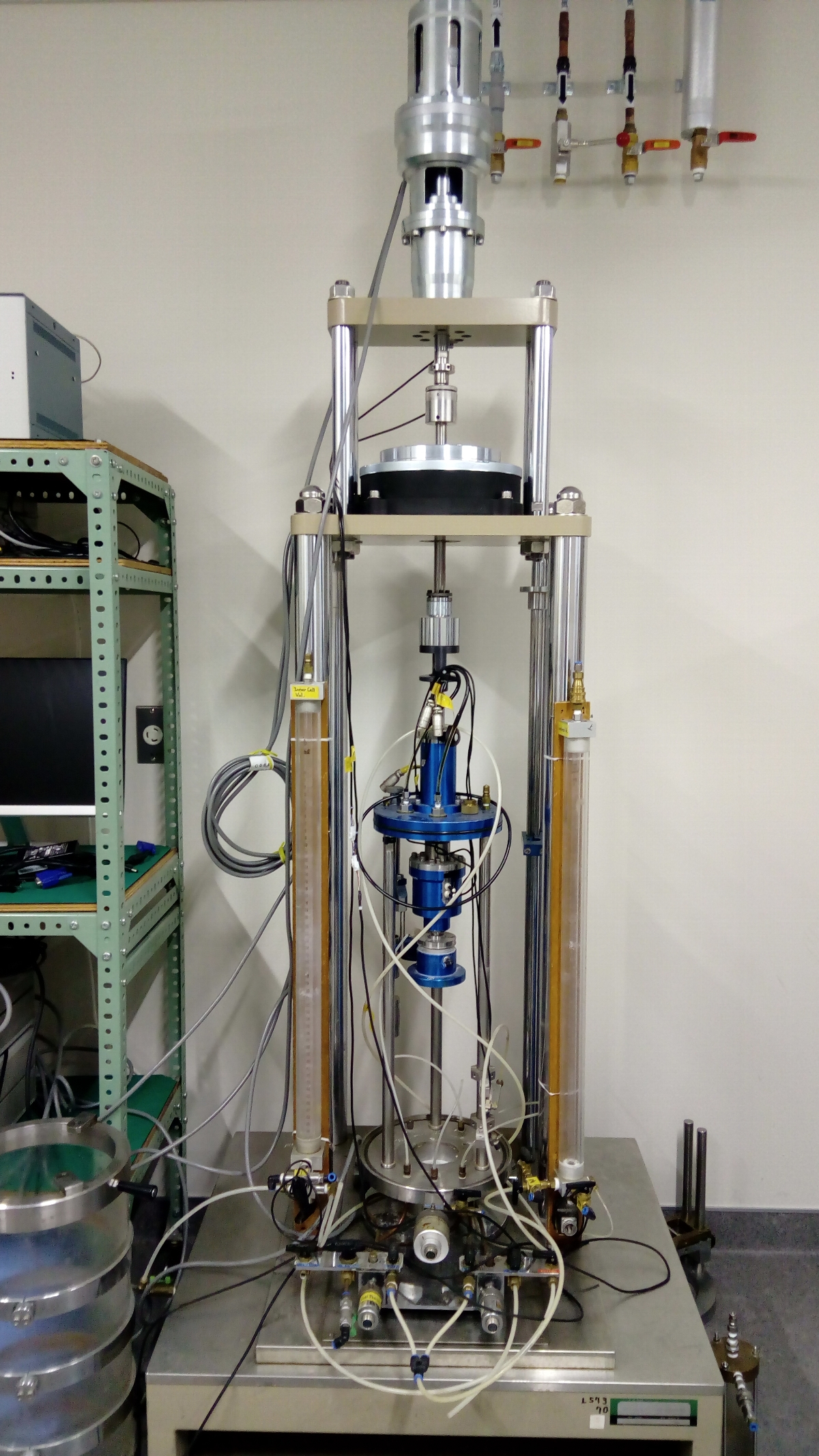

Hollow Cylinder Apparatus (HCA)

Originally manufactured by Seikensha, and now updated to our original design. The loading system has been completely renovated, with two Megatorque motors - one controlling the axial ram movement, and the other controlling the ram rotation. Personally, I obtained BEng and PhD by using HCA, so have special attachment to this machine (someone called me a 'hollow man' when I was a PhD student ...).

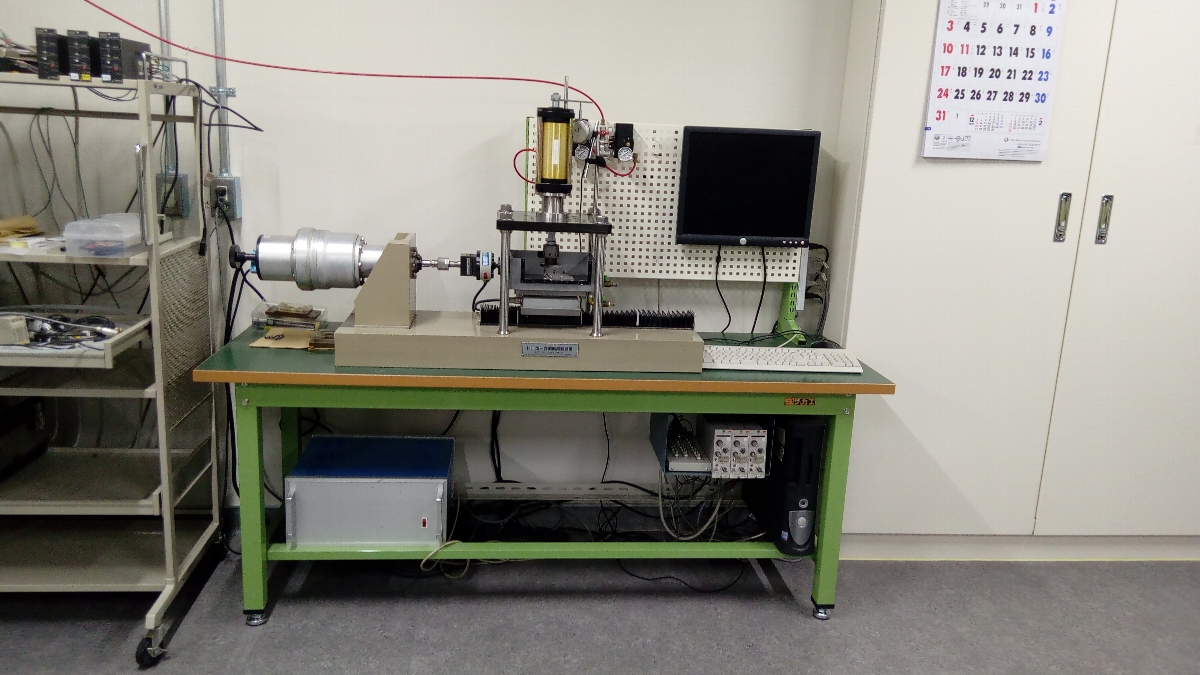

Megatorque Motor-drive Direct Shear Apparatus (DSA)

The axial stress is controlled with a double-acting bellofram pump, and the shear deformation is precisely controlled with a Megatorque Motor. Even when this apparatus is not used for direct shear, it can be used as a preconsolidation frame.

Temperature-Controlled Low-Pressure Oedometer

This is an original device intended to conduct one-dimensional compression under controlled temperature (5-50oC). An oedometer cell, which is sealed and can therefore be back-pressurised, is housed in an outer cell. By circulating temperaure-controlled medium between the innter and outer cells, the soil specimen temperature is controlled. As the displacement transducer is located outside, it is free from the temperature effect. This apparatus is being used for thermo-mechanical study of peats, which experience relatively low stress in field (and hence the load is given as dead weight in this apparatus).

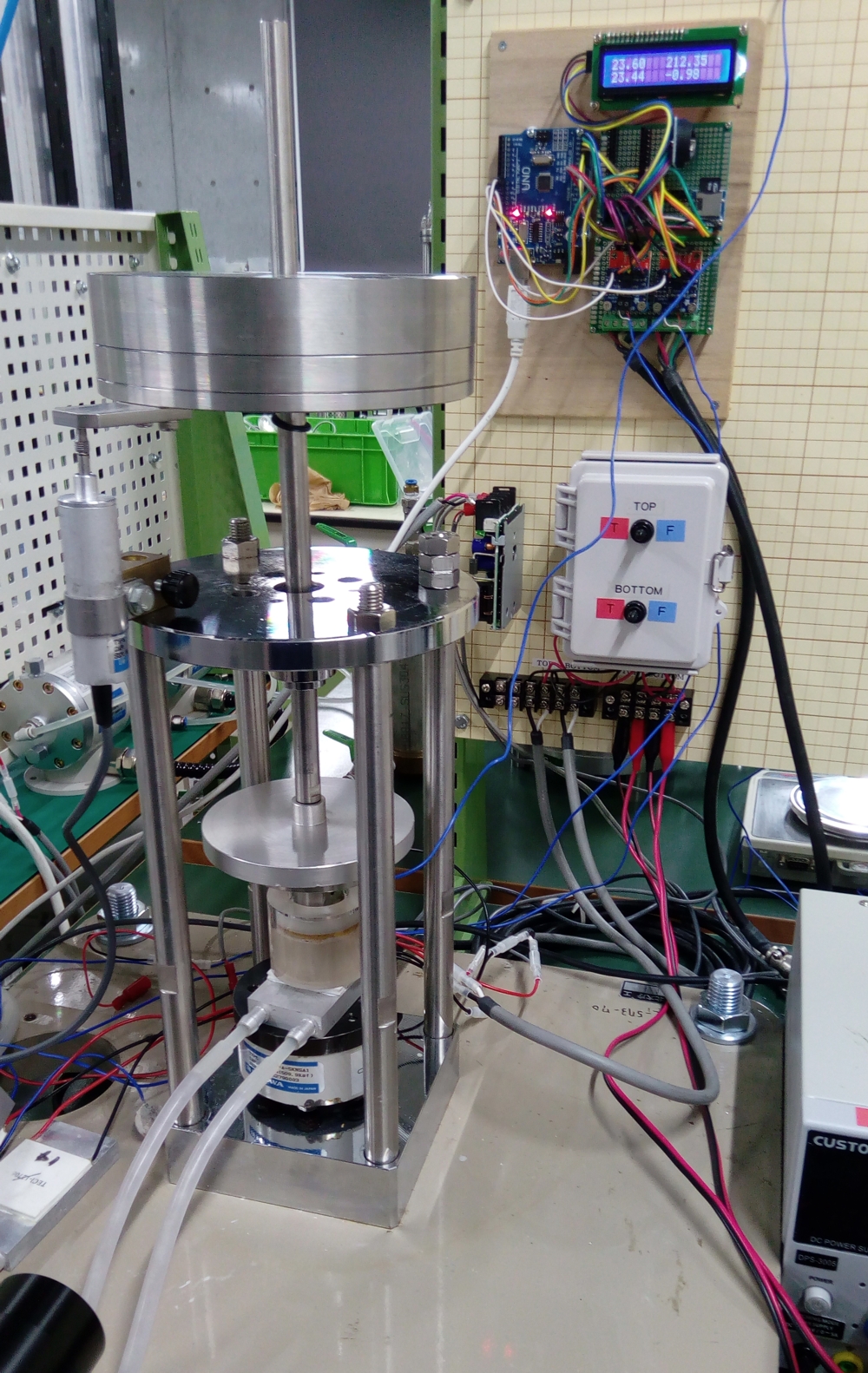

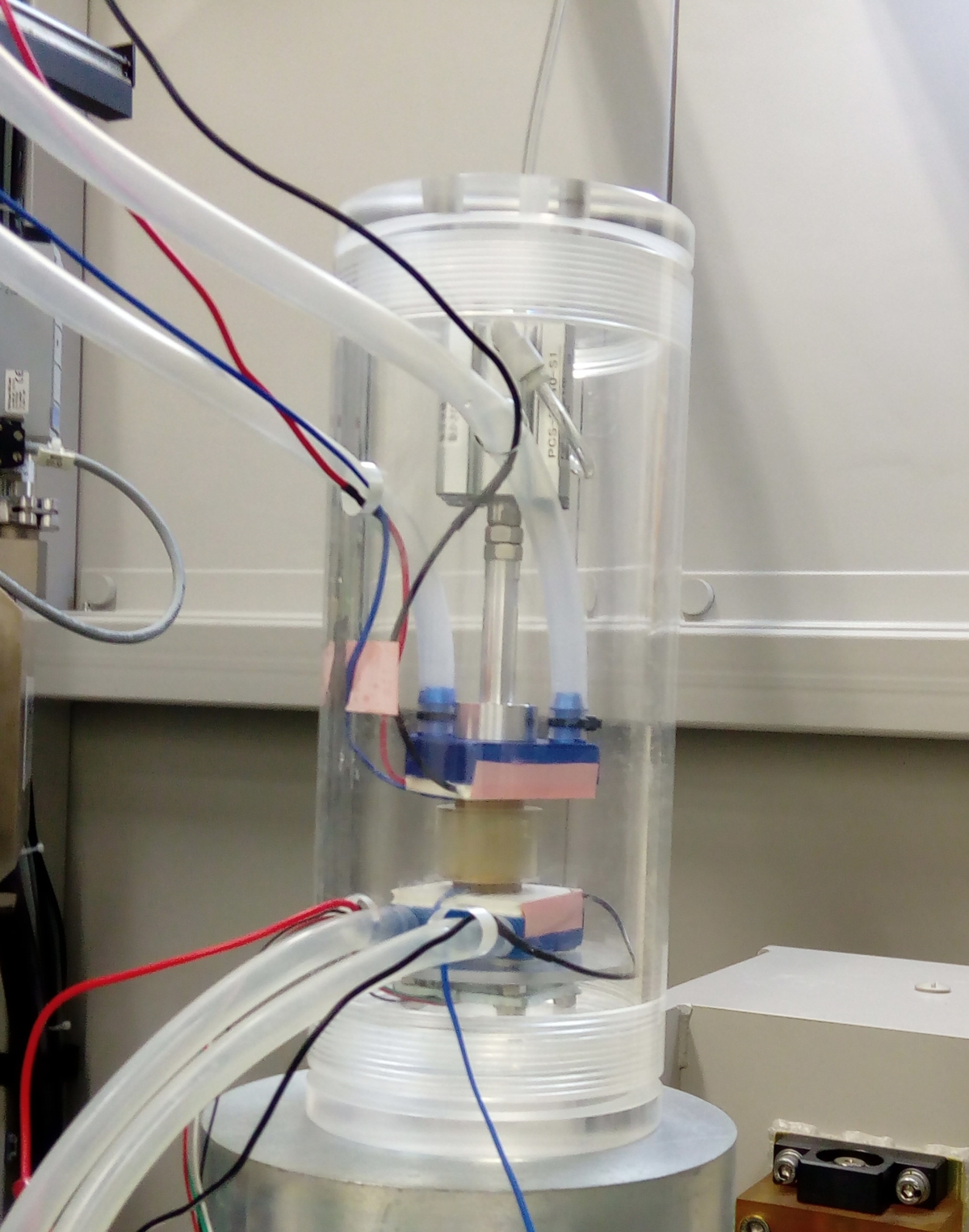

One-Dimensional Freeze-Thaw Device

This is also an original design, combining oedometer and frost-heave apparatus. By adopting a small soil specimen size and a quick Peltier freezing system, the soil specimen can be coolede to -20oC in a few minutes. Freezing and thawing can be seasily switched, and any volume change is measured. The right figure shows an alternative version, which is constructed with acrylic body, and hence allows X-ray tomography. In this version, the axial load is provided by a miniature bellofram pump.

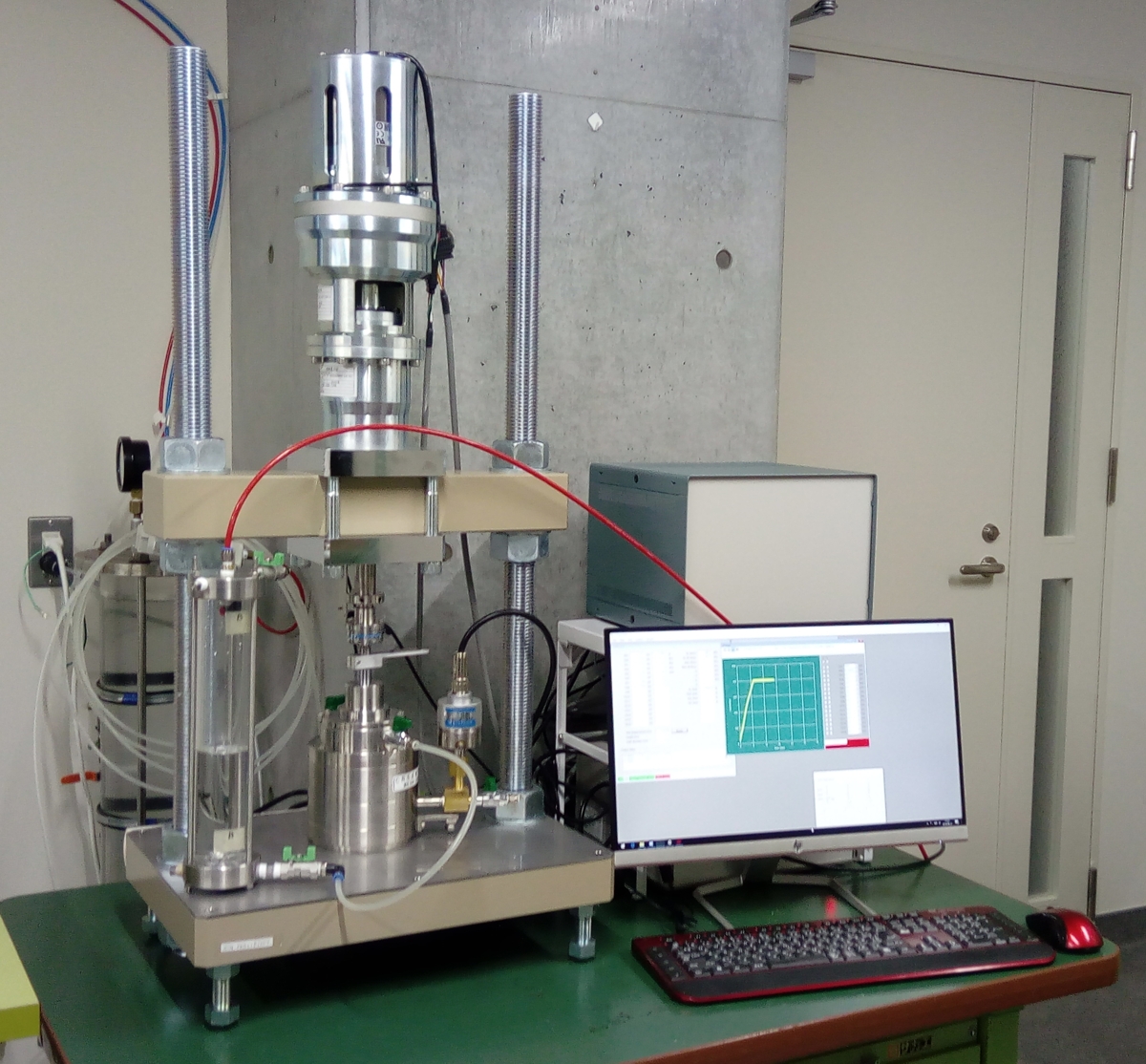

Constant-Rate-of-Strain (CRS) Oedometer

Our Constant-Rate-of-Strain (CRS) oedometers also adopt a Megatorque Motor for axial displacement. They are driven by our home-grown software Cockpit, and allows multi-stage programming via the same interface as for triaxial tests.

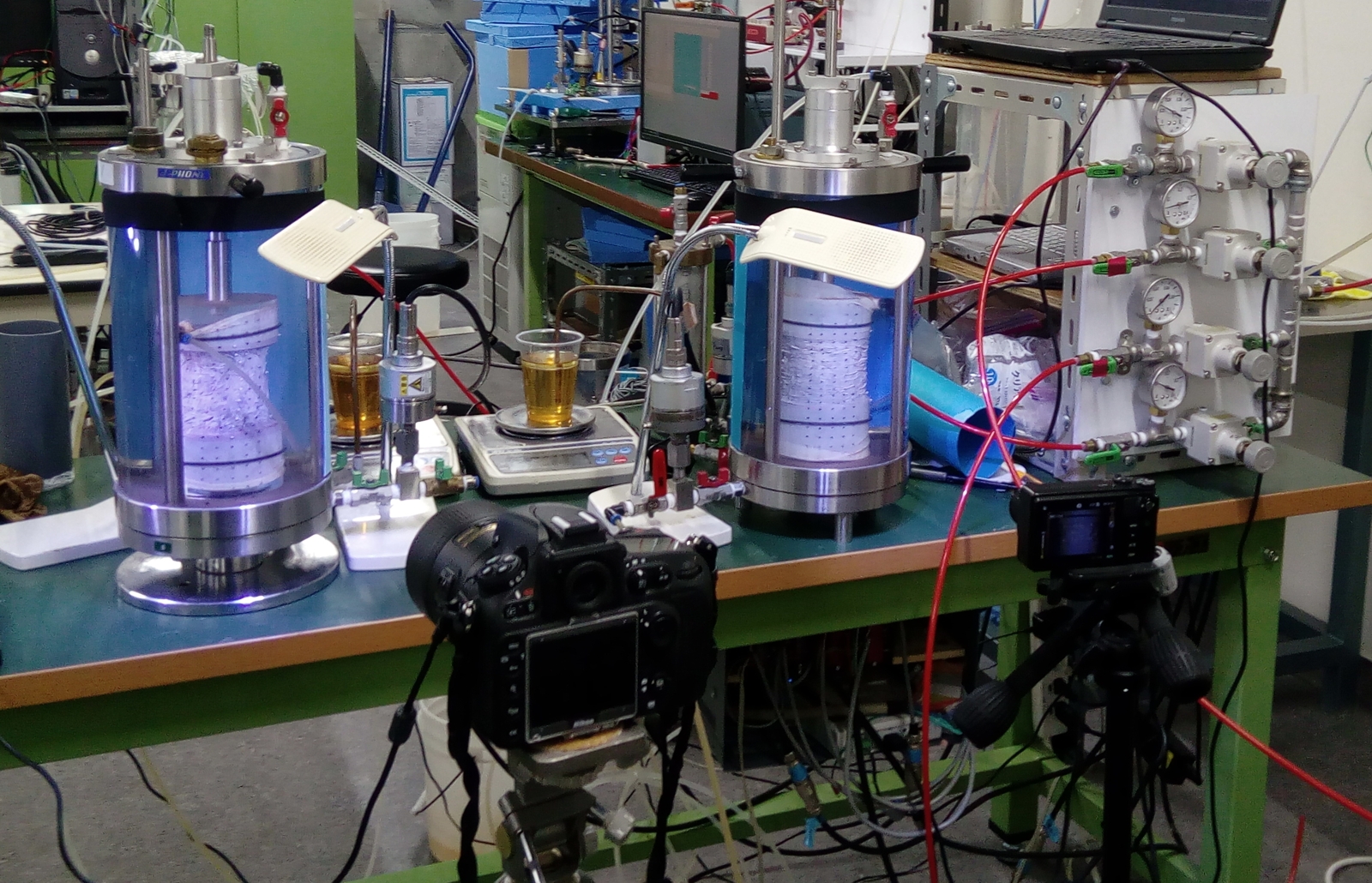

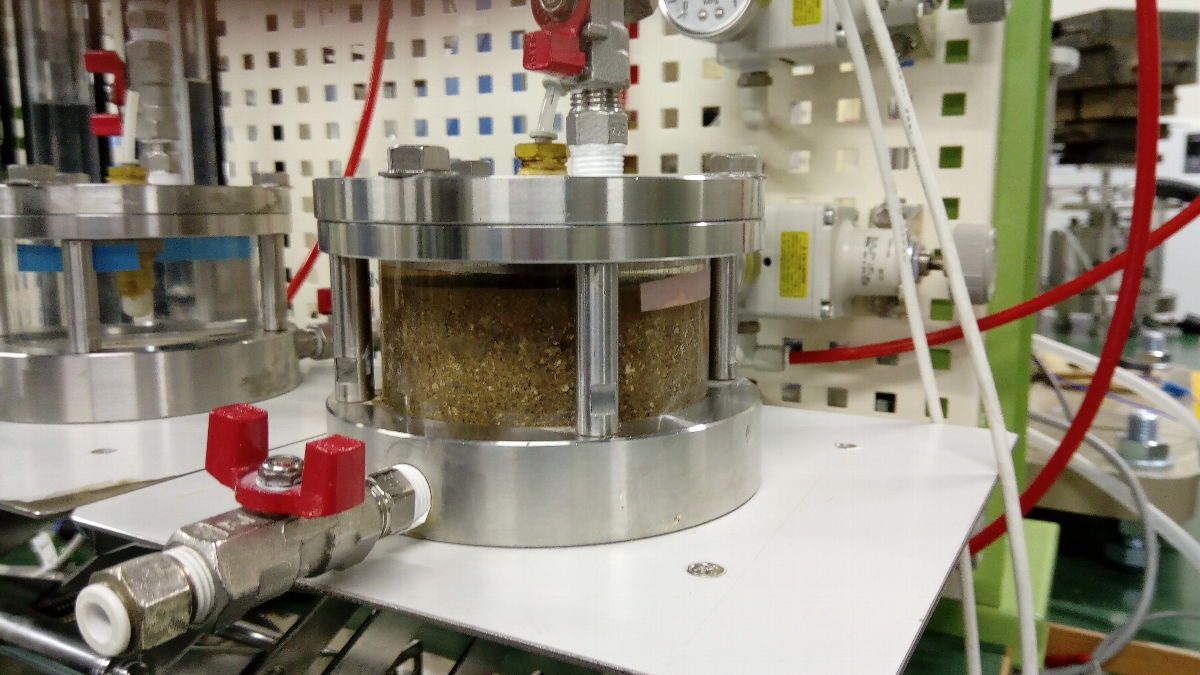

Isotropic Compression Cell / Constant-Head Peameameter

These are constant-head permeamter cells with isotropic compression capability. While isotropically compressing, the pore water pressure at the two ends can be controlled, and the outflow of the water can be measured very precisely by using an electronic balance. This equipment is intended for low-peameability soils with significant density-dependence of permeability (such as peats). In peats, a specimen deforms significantly. The deformation is therefore quantified by image analysis, so that exact volume and cross-sectional area are known at any moment.

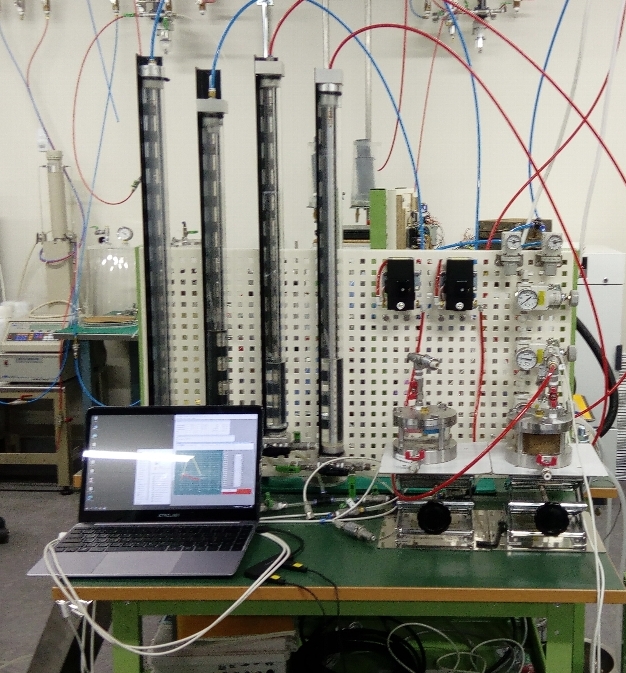

Continuous-Pressurisation (CP) Type Soil-Water Characteristics Testing Apparatus

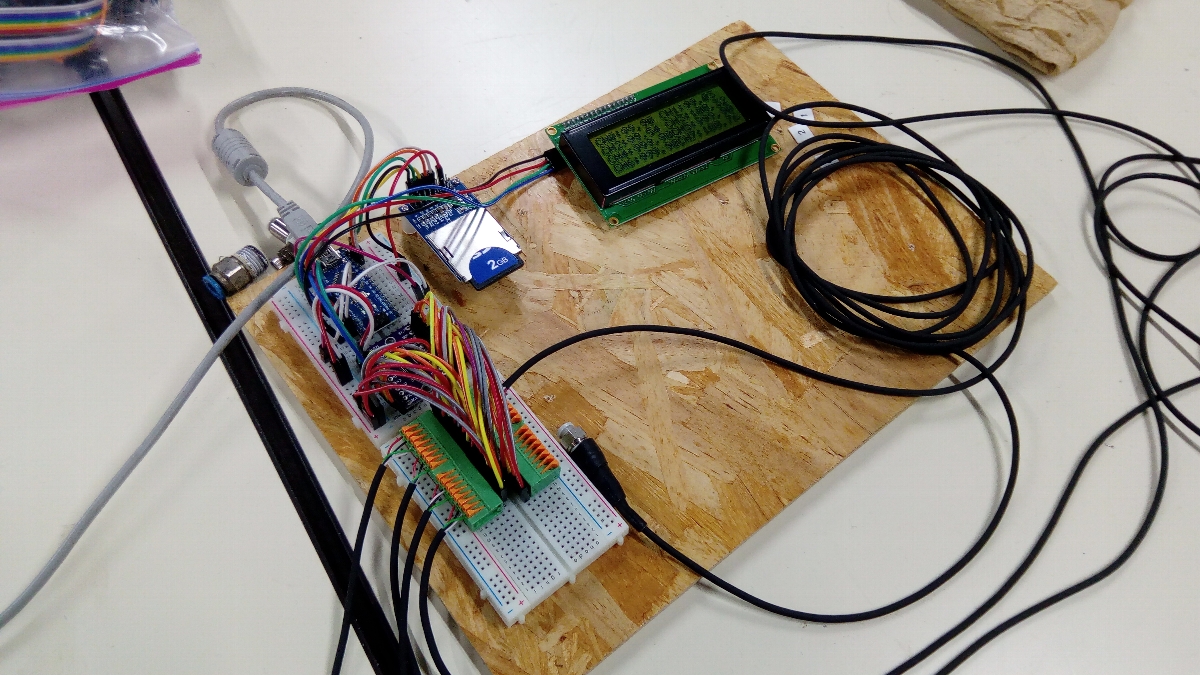

The principle of this appaaratus was originally invented by OYO Corporation. Much of the hardware is same as the conventional pressure-plate apparatus for soil-water characteristics curve measurement. The only differences are that the air pressure is automatically and continuously changed by an electro-pneumatic (EP) transuducer, and that the pore water pressure at the core of the specimen is measured by a miniature tensiometer installed in the centre. The control and data aquisition are automated with Cockpit software and home-grown interface (see Workshop page).

Much of the apparatus in our lab was originally developed. Our work bench is always busy with new development, updating, and repairing work.