The ultimate goal of our field of research is the creation of a society of energy homeostasis. To achieve this goal, we are pursuing materials and processes capable of high-density energy storage, energy transportation, and high-efficiency energy conversion. Specifically, we are pursuing research focused on (1) next-generation heat storage materials capable of high-density storage and transportation of solar heat and process waste heat; (2) energy-saving air separating & oxygen manufacturing processes that apply exergy recovery principles; (3) new iron manufacturing processes that use low-grade lime and ammonia as fuel; (4) fast, energy-saving synthesis of fine ceramics through combustion synthesis; and (5) eco-friendly industrial complex design.

Latent heat storage technology using phase change materials (PCMs) offers the potential for high-density heat storage due to the latent heat from the PCMs transition between a solid and a liquid phase. This technology is also capable of recovering, transporting, and supplying heat through phase changes occurring at a fixed temperature. Our group is developing new PCMs suitable for a variety of temperatures from room temperature to 500 deg C and above; we are also executing process design. Specifically, we are developing 1) high-conductivity PCM composites to provide heat-control technology for next-generation power devices; 2) sugar alcohol-based PCMs to utilize unused heat in low-to-mid temperature ranges (waste heat and solar heat); and 3) alloy PCMs for exergy recovery technologies and solar thermal power generation.

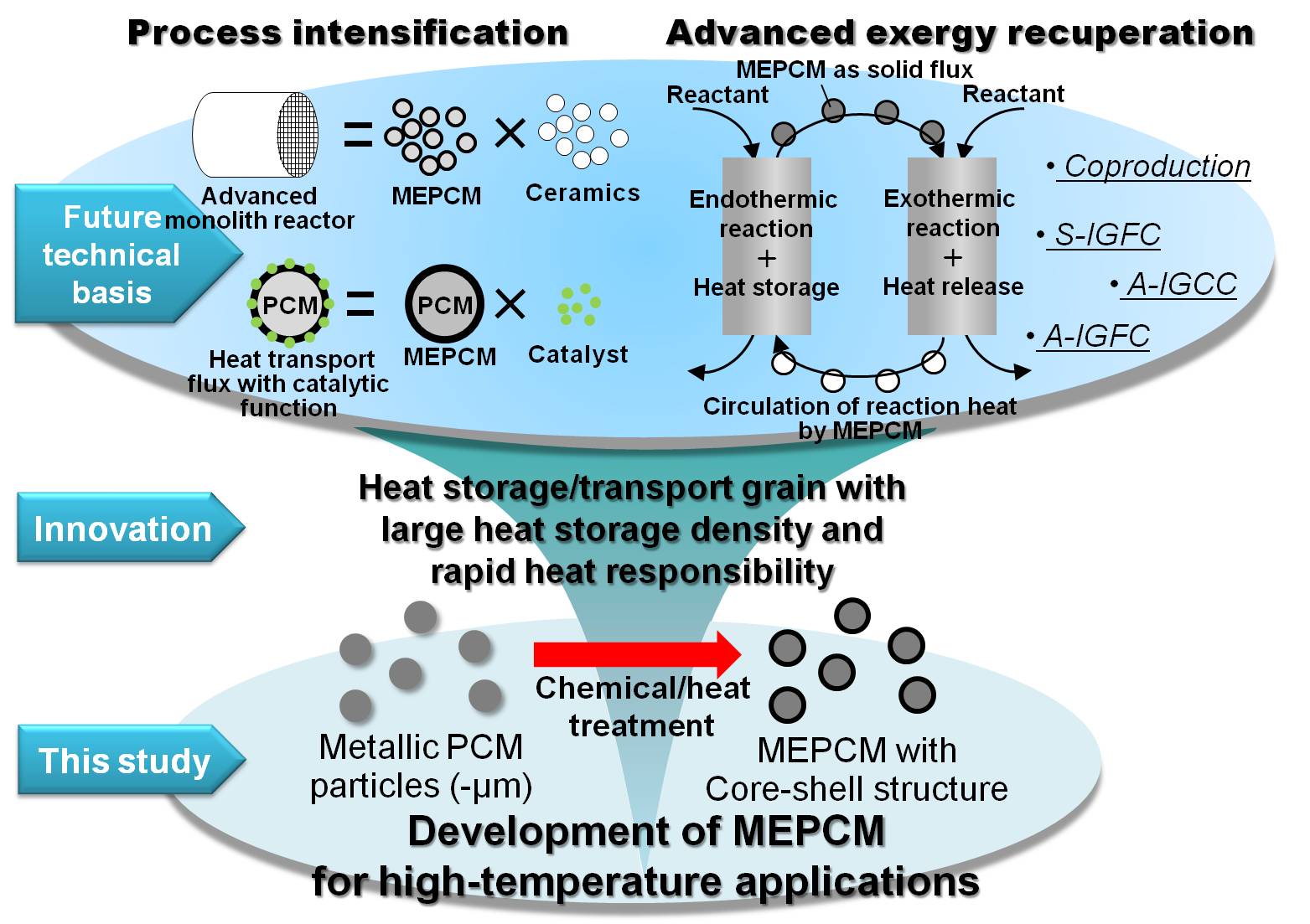

In particular, we have recently developed a microcapsule PCM usable in areas where temperatures exceed 300 deg C. This technology has the potential to revolutionize the basis of heat storage and transportation technologies in high-temperature processes for which solid sensible heat storage technology has long remained unchallenged (see Fig. 1).

Fig. 1 Expected MEPCM applications. Ref. T. Nomura et al: Sci. Rep., 5(2015, 9117.

We are developing an oxide-based oxygen-storing material capable of separating oxygen from air using only a slight pressure swing. The use of this material has been determined to have the potential to produce oxygen using less than half the energy of traditional air-separation technologies.

The exergy-intensive steel industry faces three challenges: resources, the environment, and energy. Our group is approaching this triple threat from the perspectives of materials science and process engineering to find solutions. Specifically, we are conducting research from a wide variety of perspectives, from basic experimentation to process design and system creation, with 1) technology that uses chemical vapor infiltration (CVI) to improve the quality of low-grade raw fuels, 2) a ground-breaking NH3 ironmaking technology that uses NH3 as a reduction material, and 3) technology that makes effective use of the steelworks high-temperature waste heat, implemented as key technologies.

Combustion synthesis that uses the self-propagation of an exothermic reaction between powdered materials has the potential to synthesize materials via a quick, energy-saving process. Our research laboratory has spent many years investigating combustion synthesis methods and has succeeded in synthesizing a variety of materials, such as nitrides, oxynitrides, perovskite, and hydrogen storage alloys. In recent years, we have had a particular focus on nitrides (such as AlN,Si3N4, and BN) and oxynitrides (SiAlON). For example, AlN, Si3N4, and BN are appealing as heat dissipation materials for electronic components due to their high heat conductivity and capacity for electric insulation. As the basis of our combustion synthesis technology, our group is conducting research into new functional materials created through doping nitrides and oxynitrides with trace elements and controlling the shape of the materials (such as nanoparticles and nanofibers; see Fig. 2). We are also identifying and clarifying the mechanisms through which these materials functionalities express themselves.

Fig. 2 A photo of a CS process

Here, our goal is system design that minimizes the total of losses using exergy and a true energy evaluation scale. We are also conducting analyses using cutting-edge network theory to keep systems in homeostasis and make use of eco-friendly industrial complex design where different types of businesses coexist.