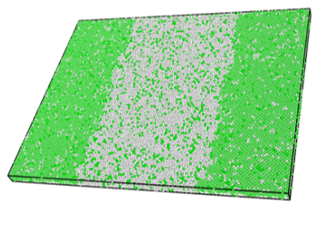

1. Mathematical modeling and numerical simulations of microstructures in metals

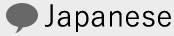

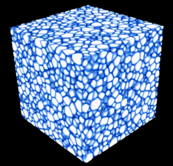

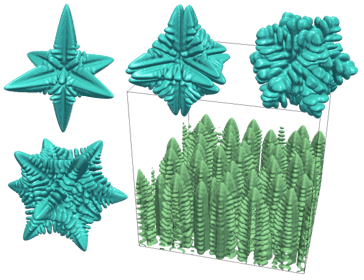

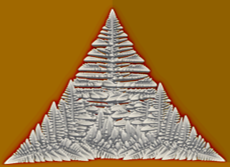

The main focus of our research is development and application of mathematical models for microstructural evolution/devolution processes in metallic materials to a wide range of phenomena such as dendritic growth, grain growth and precipitation during solidification, casting, welding and various kinds of heat treatment processes. Our focus is especially directed at development of phase-field models that are effective and powerful methods for simulating microstructural processes.

【Introduction to Metallurgy】What is dendrite?

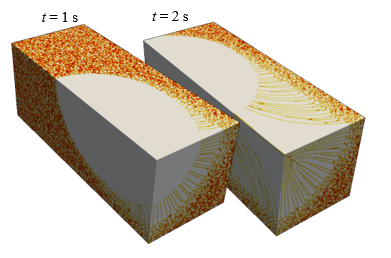

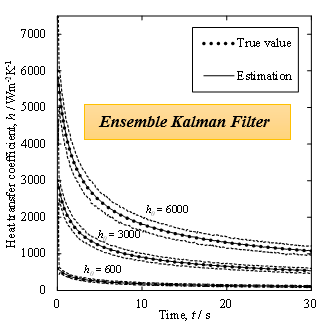

2. Parameter estimations based on data assimilation

One of our research interests is application of data assimilation, a method of data science, to estimation of parameters necessary for mesoscale simulations for microstructural evolution processes and macroscale simulations for various casting processes.

An example of estimation of heat transfer coefficient during ingot casting of Al-Cu alloy is shown in figure on the right-hand side. It shows that the ensemble Kalman filter enables accurate estimation of time-dependent heat transfer coefficient without any prior knowledge about its dependence.

Our effort is furthermore devoted to parameter estimation of solid-liquid interfacial properties based on data assimilation technique using molecular dynamics simulations.

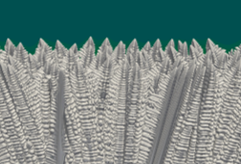

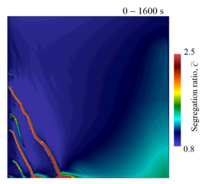

3. Accuracy improvement and acceleration of macrosegregation simulation model

We are working on development of computational approaches for simulating formation process of macrosegregation in continuous casting and ingot casting of materials. Prediction of macrosegregation requires accuracy improvement and acceleration of macrosegregation simulation models. In our group, machine leaning is applied to improvement of accuracy of microsegregation calculation in the macroscale model. Moreover, the macroscale simulation is accelerated by using lattice Boltzmann method for simulating the fluid dynamics.

4. Atomistic analysis of microstructure based on molecular dynamics simulations

Our group studies atomistic behavior related to formation processes of microstructures using atomistic simulations such as molecular dynamics simulations. Our current interests are statistical aspect of homogeneous nucleation processes during solidification and solid-liquid interfacial properties in metallic materials.

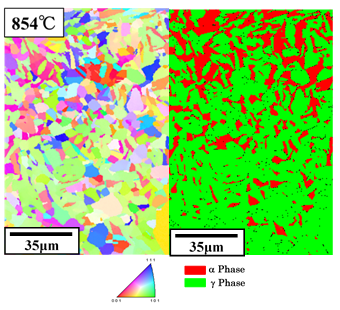

5. Controlling of microstructures in steels

Our group studies formation processes of microstructures in steels by means of experimental techniques. For instance, our studies focus on mechanism of emergence of abnormal grain growth during high temperature carburization of steels and optimal condition for alpha-gamma inverse transformation and precipitation of carbides, nitrides and carbonitrides for grain refinement of austenite grain structure.