- HOME

- Wow! Cool Laboratory [Researcher Introduction]

- Motohiro Sato

Wow! Cool Laboratory [Researcher Introduction]

Division of Mechanical and Space Engineering,

Research Group of Materials and Fluid Mechanics,

Laboratory of Strength of Materials

Field of research: Structural mechanics, Mechanics of materials, Structural stability

Research theme: Mechanics of shell structures, Buckling analysis

E-mail: tayu[a]eng.hokudai.ac.jp

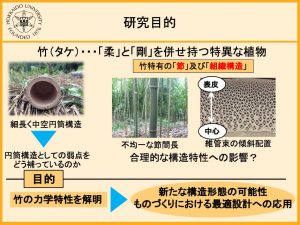

Proving the rationality of bamboo from the perspective of structural/material mechanics

Utilization for the design and development of new materials and structures

Elucidation of the relationship between bamboo stiffness and node distribution in terms of structural mechanics

Professor Motohiro Sato specializes in cylindrical objects in the subfield of structural mechanics in civil and mechanical engineering. His research has addressed various such objects, from submerged floating tunnels to carbon nanotubes, with the aim of theoretically elucidating differences in buckling and stiffness that result from structural characteristics, including differences in scale and materials.

“I’ve focused on the mechanical rationality of the structure of plants, and I think there might be something I can learn from the shapes that plants have developed over the course of their evolution.”

He has investigated bamboo, which is often seen in Japan. It has peculiar characteristics: Despite its hard skin, it’s supple and hard to break, and it has nodes and cavities. Professor Sato has analyzed how the number and spacing of the nodes, the diameter of the culm and the thickness of the woody part relate to the characteristics of bamboo from the viewpoint of structural mechanics.

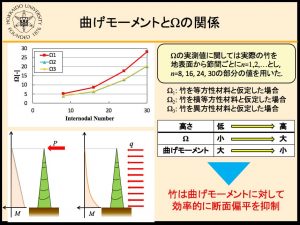

“Bamboo grows so fast; it can grow as much as a meter a day,” Professor Sato says. “It has a hollow inside so that it reaches great heights really quickly. But if it were hollow from bottom to top, it would bend if a force such as a crosswind were applied. It’s thought that there are nodes in some places to prevent such bending. But too many nodes would make the bamboo too heavy and would slow or stop its growth. So I predicted that the minimum number of nodes would be rationally arranged for maximum effect.”

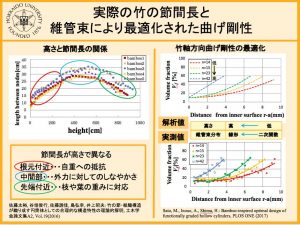

Professor Sato collected 50 bamboo stalks from a bamboo grove in Nagano Prefecture, and he studied the distribution of the nodes from base to tip. In general, the nodes are spaced at short intervals at the base and tip and at longer intervals in the middle. His analysis revealed that all 50 bamboo stalks had a node distribution that was optimized for the overall bending moment (Note 1).

“We were surprised when We actually calculated it. The bamboo structure was mechanically proven to be ideal, and bamboo was proven to be a natural functionally graded material.”

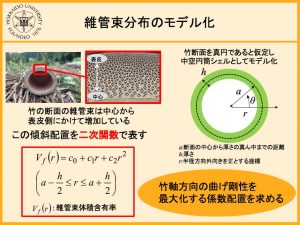

The density of the vascular bundles in the woody part is consistent with mechanical theory.

Another important characteristic of bamboo contributes to its lightness and strength. This is the distribution of fibers in the woody part. The woody part of bamboo is composed of a collection of thin, durable fibers called “vascular bundle sheaths.” The vascular bundles of bamboo have the same stiffness as steel. The cross section of a bamboo stalk shows that the fiber density increases from the inside to the outside. Professor Sato compared the bending stiffness derived from mechanical theory with actual measurements of bamboo and found that the distributions of fibers at the base, the middle and the tip maximize the bending stiffness (Note 2). The results of this analysis were featured in the scientific journal Newton (August issue of 2017).

“Many people study bamboo from the perspective of botany and use bamboo as a material. However, few people research the relationship between bamboo’s unique shape and mechanics. In this respect, I think it’s a very interesting theme.”

The development of new materials utilizing the “efficient structure” of plants

Professor Sato wants to apply these results to the development of new hollow cylindrical structures. One application is for upgrading bamboo itself. For example, injecting resin into the vascular bundles may lead to the development of a new material, so-called “hybrid bamboo.” Another is the development of a new material that mimics the structure of bamboo. He believes that by referring to the density distribution of the vascular bundles, it’s possible to develop a material whose various characteristics can be set according to use and purpose.

“Learning from plants doesn’t just mean mimicking them based on a good rule of thumb. I think it’s important to theoretically elucidate why such characteristics exist and by what mechanism their functions are exhibited before such characteristics and functions are used. I want to develop a new way of thinking about manufacturing based on the various shapes hidden in nature.”

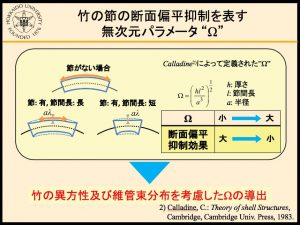

| Note 1. | Internode length measurements The part of the bamboo with the highest bending moment is the base. Accordingly, it’s thought that many nodes form at the base to reduce the risk of failure. Calculations of the correlation between the Ω distribution and the internode length show the distribution of bamboo nodes to be mechanically rational (Figures 2 and 3). |

|---|---|

| Note 2. | Optimal distribution of reinforcing fibers The results show that the gradient distribution for maximizing the bending stiffness, which was deduced from dynamic theory, is perfectly consistent with the measured bamboo fiber distribution (Figures 4 and 5). |

Professor Sato says he wants to find out the principles common to various cylindrical structures—from civil engineering structures, such as bridges and tunnels, to carbon nanotubes. |