- HOME

- Wow! Cool Laboratory [Researcher Introduction]

- Takahiro Nomura

Wow! Cool Laboratory [Researcher Introduction]

Center for Advanced Research of Energy & Materials,

Laboratory of Energy Media

Field of research: heat storage, oxygen storage materials, exergy, ironmaking

Research themes: high-density storage, transportation and conversion of energy, creation of a homeostatic-controlled energy-oriented society

E-mail: nms-tropy[a]eng.hokudai.ac.jp

PCM enabling the high-density storage and transportation of thermal energy

Expected to be applied in the industrial, chemical and various other fields

Ecological industrial complex where exhaust heat from ironmaking industry is effectively used in other fields

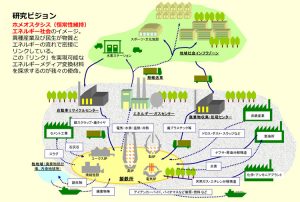

With the creation of a homeostatic-controlled society as the ultimate goal, the Laboratory of Energy Media of the Center for Advanced Research of Energy & Materials attached to the Faculty of Engineering works on the development of materials that densely store, transport and efficiently convert energy, and the evaluation and design of systems applying a theory based on exergy (indicator of energy quality).

“Homeostasis is a biological term meaning the phenomenon when a biological system maintains equilibrium. We think that a homeostatic-controlled energy-oriented society can be realized by creating a link that continuously circulates energy and developing technology to efficiently use energy. We conduct research to realize an energy-oriented society in which different industries and the household sector are closely linked in the flow of materials and energy (= a homeostatic-controlled energy-oriented society).”

Although there are energy issues around the globe, 60% of input primary energy is estimated to become unused heat (i.e., exhaust heat) in Japan. The laboratory conducts research to develop technology that enables the reduction of fossil-fuel consumption and promotes energy recycling through the effective use of exhaust heat. Specifically, the lab’s researchers are working on the design of an ecological industrial complex with ironworks at its center (note 1). It is a symbiotic system in which exhaust heat, other energy and byproducts from ironworks are reused in linked different industries (e.g., cement plants, refineries and chemical plants).

Development of metal/alloyed latent heat storage materials toward high-temperature heat source recovery

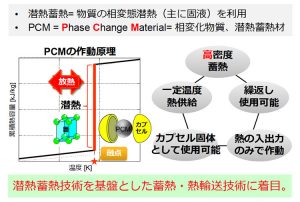

Energy storage technology enables such a link. Energy storage technology includes batteries and hydrogen, which function to store chemical energy, and dams, in which potential energy is stored. Technology to store heat, which is generated in enormous quantities, and a platform for energy system input are especially attracting attention from various fields. Associate Professor Nomura works on the development of metal/alloyed latent heat storage materials toward high-temperature heat source recovery.

Latent heat storage materials are materials that can store and release latent heat produced during the phase transformation of matter, and are called PCM (phase change materials). Associate Professor Nomura conducts research and development on technology in which an Al-Si alloy is used to fill a ceramic capsule to use heat storage and heat release at the time of the phase transformation of the Al-Si alloy (solid – liquid) (note 2). The PCM of the Al-Si alloy have advantages including (1) high-density heat storage, (2) heat release at a fixed melting point and (3) easy reusability. With the aim of recovering industrial waste heat at 100℃ to 1000℃, research is conducted to develop PCM that can store energy efficiently and put it into practical use.

Regarding the above-mentioned ecological industrial complex, it is assumed that waste heat from ironworks is stored in PCM, which are transported to other business establishments for recycling or repeatedly used in the same business establishment.

“Concerning the needs for the effective use of waste heat, PCM is expected to be not only used for recovering waste heat generated in industry but also applied to waste heat recovery in hybrid cars and electric cars. The technology is also attracting attention in the renewable energy field, for example, for application to solar power generation and as a heat storage system for heat storage generation and wind-force thermal power generation.”

Successful microencapsulation has widened the range of application.

Hokkaido University-led commercialization project has also started.

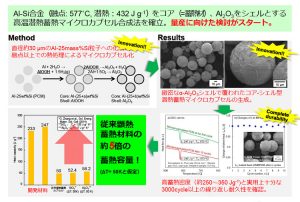

In 2014, the laboratory succeeded in the microencapsulation of PCM (note 3). A microcapsule was synthesized with the Al-Si alloy as the core (latent heat material) and Al₂O₃ (aluminum oxide) as the shell. The 30-micron ceramic particle has made it possible to mold heat reservoirs with diverse materials and shapes. It is the world’s first development of a latent heat storage microcapsule that can be used in a high temperature area.

“Microencapsulated PCM (MEPCM) have heat storage capacity five times greater than conventional storage materials. They can be processed and molded as particles to be mixed with various materials and can also be used in various forms, ranging from the solid to liquid forms. In addition to heat storage/transportation devices and heat storage systems for renewable energy systems, they can be applied to the base of new technology, such as the development of a catalyst with a thermal control function by uniting MEPCM with a catalyst. The industrial world places high expectations on MEPCM.”

Hokkaido University reserves all information and technology on MEPCM within the school and has launched a project to promote collaboration with companies in diverse fields. The university plans to commercialize MEPCM, a technology created at Hokkaido University, and spread it in society.

Associate Professor Nomura expects that the development of various types of PCM at low to high temperatures may lead to the discovery of new materials, physical properties and functions. |