- HOME

- Wow! Cool Laboratory [Researcher Introduction]

- Masaru Kikuchi

Wow! Cool Laboratory [Researcher Introduction]

Division of Architectural and Structural Design,

Research Group of Structural and Urban Safety Design,

Building Structure Control Laboratory

Field of research: structural engineering, seismic engineering, earthquake engineering, vibration engineering

Research themes: seismic isolation, seismic retrofitting, historical structures, elastomeric isolation bearings, vibration control

E-mail: mkiku[a]eng.hokudai.ac.jp

Research on the mechanical properties of elastomeric isolation bearings for the purpose of providing ultimately safe building structures

Research on elastomeric bearings, the key device in seismic isolation systems

In Japan, an earthquake-prone country, aseismic design is essential for buildings, condominiums and houses. Aseismic construction is divided into the earthquake-resistant type, in which a building itself is strengthened, the seismic isolation type, in which earthquake vibrations are prevented from transmitting through a building, and the vibration control type, in which building vibrations are damped and converted to thermal energy. Professor Masaru Kikuchi of the Structural Design Laboratory is a leading researcher who has studied seismic isolation over the past 30 years.

“I encountered seismic isolation technology in the late 1980s. In those days, that was a new technology little known in the world, and research on such structures had just begun in Japan, the United States, New Zealand and Italy. Of course, lectures on seismic isolation technology were not offered in Hokkaido University. After graduating from the university, I got a job at a construction company and was involved in the project on the research and development of seismic isolation technology in my department”

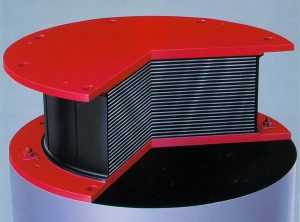

The key component of a seismic isolation structure is an elastomeric isolation bearing (note 1). A typical seismic isolation system consists of isolators that support a building weight and deform in the horizontal direction (there are such types as rubber, sliding and ball bearings) and dampers that damp the vibration of the structures. An elastomeric isolation bearing exhibit s breaking or buckling behavior under extremely large shear deformation induced by low-frequency earthquake ground motions. Professor Kikuchi has conducted research on high-damping rubber bearings, which are made by blending carbon and resin materials into a mixture of natural and synthetic rubber. This is a revolutionary technology that gives us a great advantage in reducing seismic response acceleration in building structures without any dampers. Moreover, it enables us to shorten the construction period and to reduce construction costs.

In recent years, after 1995 Kobe Earthquake and the 2011 Tohoku Earthquake , seismic isolation technology has been employed for high-rise buildings and condominiums. Seismic isolation can also be applied to existing buildings by conducting reconstruction work only at the foundation level underneath a building, making the technology suitable for the seismic retrofitting of historical buildings, which need to be preserved without changing their design and facade. However, to date the number of seismically isolated buildings in Japan is only approximately 5,000.

“No matter how superior a technology is, it is meaningless unless it is prevalent in society. I was actually engaged in construction work for a seismically isolated building, so I am absolutely sure about the outstanding advantage of the high-damping rubber bearings. I hope that we will promote them as a seismic isolation technology that is cost saving and easy in design and construction.”

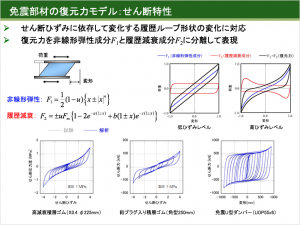

The Kikuchi Model represents the seismic response behavior of a seismically isolated building in order to verify the seismic isolation performance.

The high-damping rubber bearings are convenient devices that can constitute a seismic isolation structure by themselves without any dampers, however, one disadvantage with them is that their mechanical properties are difficult to be exactly evaluated in design. To employ all-in-one type isolation bearings, a bilinear model has been typically used for the simulation to evaluate the deformation (e.g., shear, strain) and restoring force due to earthquake ground motions. However, an ordinary bilinear model could not precisely predict the restoring force of high-damping rubber bearings.

“Design will go to waste unless the mechanical properties of rubber bearings are precisely evaluated. I needed a new analytical model to determine what type of seismic isolation structure should be used in design.”

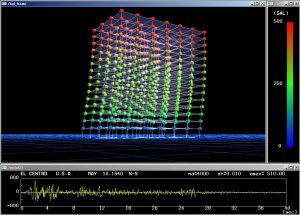

Then, Professor Kikuchi worked on the development of a hysteresis model for elastomeric isolation bearings for computer simulation in design. The model invented by Professor Kikuchi has evolved into a uniform model that can precisely predict the mechanical properties of seismic isolation devices that include not only high-damping rubber bearings but also lead rubber bearings and steel dampers (note 2). This was achieved by employing extensible mathematical expressions in the model and standardizing the evaluation method for the mechanical properties of different types of seismic isolation devices. The award of the Japan Society of Seismic Isolation in 2005 and the prize of Architectural Institute of Japan in 2015 were presented to Professor Kikuchi for his outstanding research achievements in seismic isolation technology. The model is now widely prevalent in architectural design under the name of the Kikuchi Model. More than 100 seismically isolated buildings have been designed using the Kikuchi Model in Japan. The model was also used in the design of the seismic isolation retrofitting for the National Museum of Western Art, a World Cultural Heritage site in 1998. In 2013, it was implemented for OpenSees, a structural analysis program developed at the University of California in the United States, and since then it has been used among researchers and engineers around the world under the name of Kikuchi-Aiken Model (Dr. Aiken was a research collaborator). Professor Kikuchi has also developed a 3-dimensional earthquake simulation system (note 3) to make it possible to precisely predict the response of seismically isolated buildings.

Professor Kikuchi focuses on educational activities, technical guidance and lecture meetings in Japan and elsewhere to spread this seismic isolation technology. Meanwhile, he says that not only the construction industry but also the general public should become aware of seismic isolation.

“In Japan, earthquake-prone areas used to be distinguished from areas where earthquakes rarely occur, but it is now considered that a major earthquake can occur anywhere. Within Japan, an inland earthquake could occur, and all active faults are yet to be identified. We don’t know when, where and what type of earthquake will occur. This is why I hope that everyone prepares for an earthquake and becomes interested in earthquake-resistance/seismic isolation technology.”