研究紹介

Development of novel functional devices using solid-liquid interfacial tension and chemical reaction

Research Group of Eco-Materials

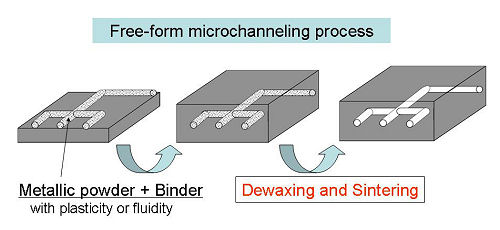

Free-form microchanneling in sintered metallic powder compacts

The method of fabricating microchannels in metal bodies is of particular interest as a core technology for producing microchannel devices such as small-scale heat exchangers or microreactors for highly exothermic reactions. The microchannel is a thin channel with a characteristic dimension of several tens or hundreds microns. We are investigating a simple and economical process for fabricating metallic microchannel devices.

The concept for our process is based on a microscopic infiltration phenomenon that often occurs during liquid phase sintering of a powder mixture of different metals, e.g., the mixture of titanium and aluminum. In our microchanneling process, a shaped compound of aluminum powder and an organic binder is used as a sacrificial core. The powder-binder compound is formed into the same shape as the intended microchannel-network by a micro-injection process.

A titanium-powder compact containing the sacrificial core is sintered at a temperature above the melting point of aluminum. During sintering of the powder compact, the organic binder is removed and liquid aluminum originating from the aluminum powder flows into narrow capillaries between the titanium powder particles and reacts with the titanium particles to produce Ti-Al alloy layers lining the cavity formed at the sites initially occupied by the powder-binder compound.

The composition, phase, structure and function of the lining layers can be changed by the heat treatment during sintering and the addition of a third element into the powder-binder compound.