研究紹介

Oxidation, Corrosion and Protection of Metallic Materials at Elevated Temperatures

Research Group of Energy Materials

Development of Long-Life and Reliable Bond Coatings for High Temperature Materials

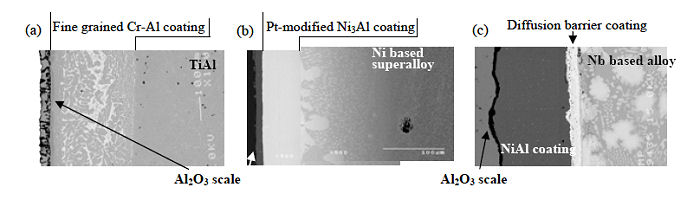

High temperature oxidation resistance coatings are developed to provide long-life and reliability for high temperature materials, such like Ni-based superalloys. Developments of advanced coatings, which have good oxidation-corrosion performance, long-life and reliability, have been required, since coating technology must be the key to improve the performance of gas turbine engines. Our goal of this challenge is to develop the advanced coating system, which have both good oxidation-corrosion resistance and compatibility with high temperature materials in terms of thermodynamic factors.

Figure 1 Various coatings on different high temperature materials

(a) TiAl, (b) Ni based superalloy, and (c) Nb based superalloy

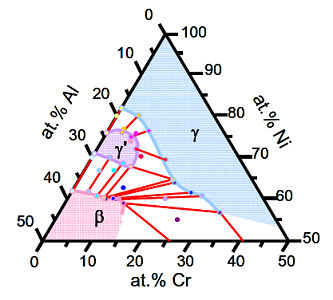

Fundamental of High Temperature Oxidation and Corrosion

Exploring of high temperature oxidation, corrosion and protection of metallic materials in various environments, such as in air, SO2, HCl so on, is to understand degradation behavior of materials and, therefore, to control high temperature performance of materials. Our research projects also involve such fundamental aspects.

Figure 2 Ternary Ni-Al-Cr isothermal phase diagram at 1150℃ developed by our research group

Numerical Simulation for Prediction of Solidified Structure

It is possible to develop new functions of materials by controlling the solidified structure of materials. In order to control the solidified structure of materials, the numerical model for predicting solidified structure of materials has been developed by using Phase-field, Cellular automaton, Monte Carlo and Front Tracking methods. Numerical simulations are carried out to investigate the mechanism of solidified structure formation and functions of materials.

Figure 3 Results of simulation for solidification