研究紹介

New Frontier of Metal Surface Technology

Research Group of Materials Design

Fabrication of Anodic Oxide Films with High Dielectric Property

Barrier type anodic oxide films can be formed on aluminum, tantalum, and niobium by anodizing. These oxide films are used as dielectric films in electrolytic capacitors, and the performance of the electrolytic capacitor strongly depends on their physical and chemical properties.

We investigate the improvement of performance of electrolytic capacitors used in many electronic devices and develop new high-performance capacitors.

Development of New Micro- and Nano-Fabrication Method

Patterning of the surface of metals and semiconductors is very important to fabricate electronic devices, micro-machine, and so on. The processes of micro-patterning involve photolithography at present, but this technique is seldom applied to materials with curved surface.

We have developed new micro- and nano-patterning techniques using laser irradiation and atomic force micro-prove (AFM) processing on aluminum covered with anodic oxide films. This technique allows micro-patterning on three-dimensional (3D) surfaces, and we fabricate 3D micro-structures, such as micro-electromechanical systems (MEMS), micro-total analysis systems (μ-TAS), and bio-systems by the technique.

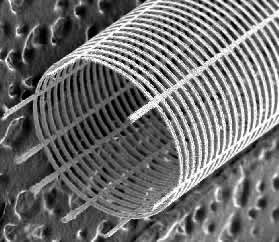

Figure 1 SEM image of the 3D nickel micro-structure

Study on corrosion and protection of metals

Aluminum- and titanium-alloy, and stainless steels are used in many industrial products, such as airplane, vehicle, electrical appliances, bio-material, and so on. These metals have high chemical stability due to thin oxide films on the surface.

Our research is focused on the galvanic corrosion of the metals and alloys and the reformation of oxide films after film removal by laser irradiation. The research target is to develop new techniques of surface modification for high corrosion resistance in various environments.